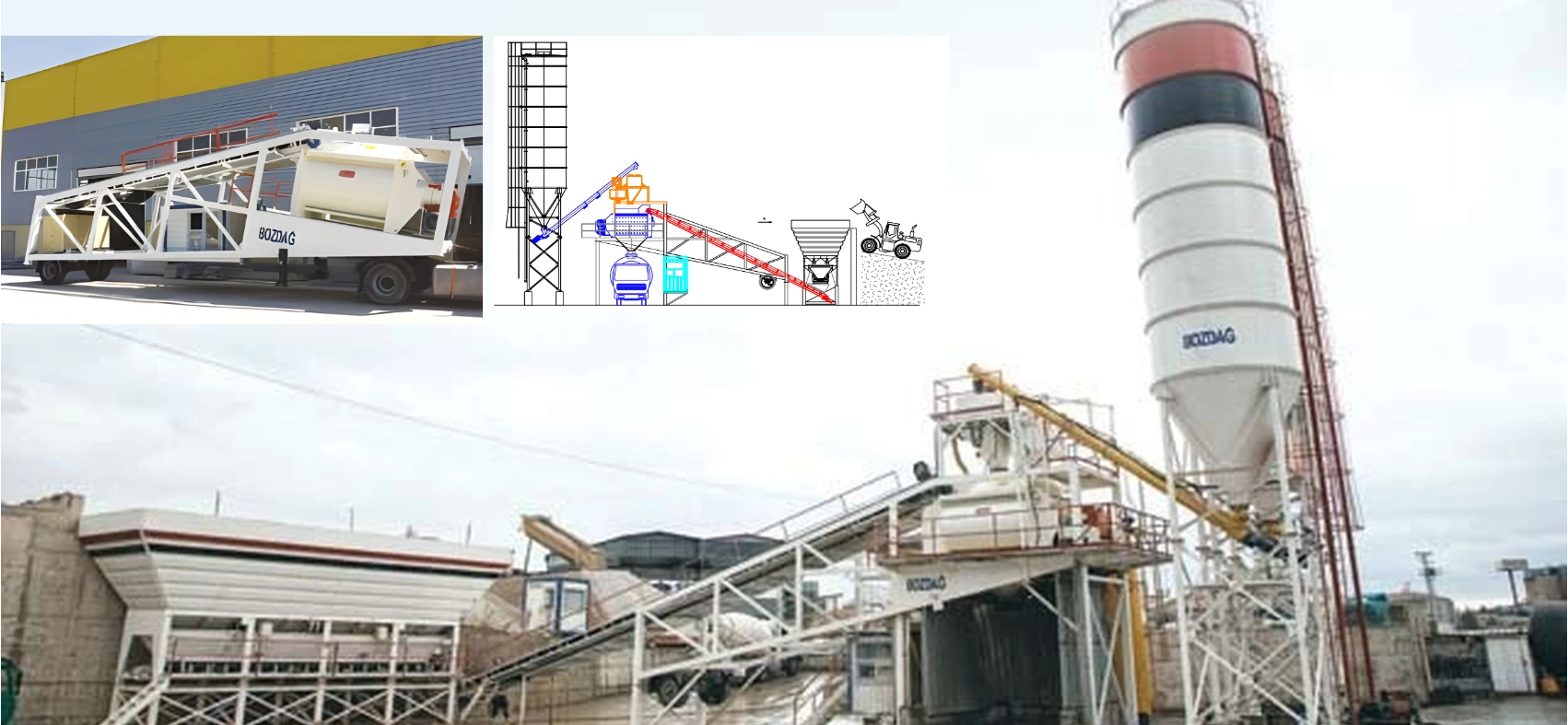

Mobile Concrete Batching Plants

Bozdağ Mobile Concrete Batching Plants deliver exceptional performance, easy portability, and fast installation — making them perfectly suited to modern construction environments. Designed with a modular system, these plants feature bolted connections and a sliding assembly system, allowing for full setup within just 2–3 days, without the need for welding. This makes Bozdağ mobile batching plants the ideal choice for companies seeking to save time and labor costs.

All core components of Bozdağ mobile concrete plants — except electric motors, gearboxes, and electronic systems — are manufactured in-house at Bozdağ’s facilities. This ensures that each plant is tailored to specific project requirements and site conditions, providing flexible solutions in different capacities and configurations.

Portability and Efficient Assembly

Bozdağ mobile batching plants are designed for single-trailer transport, with all components mounted on the main chassis. Optional feedback units further enhance operational efficiency. This design offers significant advantages in installation speed and site readiness.

Each plant can be installed at any desired location, with Bozdağ’s expert team planning site layouts for maximum efficiency and minimum operating cost.

High Performance and Durability

Built to the highest quality standards, Bozdağ mobile plants provide long-lasting performance even under the most demanding field conditions. Their compact structure ensures easy operation in limited spaces, while advanced automation systems guarantee precise weighing and consistently homogeneous concrete mixtures.

Bozdağ Mobile Concrete Plant Models

Bozdağ offers six different models to meet various project sizes and production needs:

BM 60 Mobile Concrete Plant – Ideal for small to medium-sized projects with fast setup and low energy consumption.

BM 60-S Mobile Concrete Plant – An upgraded version of the BM 60, offering higher mixing capacity and advanced automation options.

BM 100 Mobile Concrete Plant – Designed for projects requiring high-volume concrete production.

BM 100-S Mobile Concrete Plant – Dual-mixer configuration for simultaneous production of different concrete types.

BM 120 Mobile Concrete Plant – High-efficiency and stable operation for large-scale construction projects.

BM 120-S Mobile Concrete Plant – The most advanced model, offering maximum capacity, full automation, and rapid production capability.

(→ Technical specifications for each model can be found in the table below.)

Reliable Production with Bozdağ Quality

Bozdağ Mobile Concrete Plants are designed in compliance with international quality standards and manufactured domestically with local engineering expertise. They provide long service life and low maintenance costs, making them the trusted choice for both domestic and international projects.

Application Areas

On-site ready-mix concrete production

Dam, road, bridge, and infrastructure projects

Short-term and mobile concrete production requirements

With innovative solutions and a commitment to engineering excellence, Bozdağ Mühendislik continues to deliver mobile batching plant systems that add value to every construction project — from local developments to large-scale global operations.

BM 60 Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 60 m³/hour |

| Cycle Time | 60 mix/hour |

| Total Motor Power | 100–120 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Mixer Specifications | |

| Type | Planetary |

| Mixer Capacity | 1 m³ |

| Dry Capacity | 1.500 lt |

| Compressed Concrete | 1.000 lt |

| Motor Power | 45 kW |

| Aggregate Bunker | |

| Aggregate Compartments | 4 pcs |

| Compartment Capacity | 10 m³ |

| Total Capacity | 40 m³ |

| Aggregate Weighing Conveyor | |

| Width | 600 mm |

| Length | 5 m |

| Motor Power | 5,5 kW |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 500 kg |

| Water Weighing Hopper | 300 kg |

| Additive Weighing Hopper | 50 kg |

| Mixer Feeding Conveyor | |

| Width | 800 mm |

| Length | ~8-9 m |

| Motor Power | 11 kW |

| Cement Silo Equipment | |

| Cement Silo Capacity | 2×20 ton |

| Cement Silo Number | 2 pcs |

| Çimento Helezonu / Cement Screw Conveyor | Ø219 |

| Compressor | |

| Capacity | 700 lt/öin |

| Working Pressure | 6–8 bar |

| Motor Power | 4 kW |

| Optional | |

| Aggregate Loading System | |

| Aggregate Hopper Capacity | 7 m³ |

| Width | 800 mm |

| Length | 17 m |

| Motor Power | 15 kW |

BM 60-S Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 60 m³/hour |

| Cycle Time | 60 mix/hour |

| Total Motor Power | 100–120 kw |

| Voltage - Frequency | 380V / 50 Hz |

| Mixer Specifications | |

| Type | Planetary |

| Mixer Capacity | 1 m³ |

| Dry Capacity | 1.500 lt |

| Compressed Concrete | 1.000 lt |

| Motor Power | 45 kw |

| Aggregate Bunker | |

| Aggregate Compartments | 4 pcs |

| Compartment Capacity | 10 m³ |

| Total Capacity | 40 m³ |

| Aggregate Weighing Conveyor and Mixer Feeding Conveyor | |

| Width | 800 mm |

| Length | ~13 m |

| Motor Power | 15 kw |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 500 kg |

| Water Weighing Hopper | 300 kg |

| Additive Weighing Hopper | 50 kg |

| Cement Silo Equipment | |

| Cement Silo Capacity | 75–100 ton |

| Cement Silo Number | 1–4 pcs |

| Cement Screw Conveyor | Ø219 |

| Compressor | |

| Capacity | 700 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 4 kw |

| Optional | |

| Aggregate Loading System | |

| Aggregate Hopper Capacity | 7 m³ |

| Width | 800 mm |

| Length | ~17 m |

| Motor Power | 15 kw |

BM 100 Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 100 m³/hour |

| Cycle Time | 50 mix/hour |

| Total Motor Power | 150–180 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Mixer Specifications | |

| Type | Twin Shaft |

| Mixer Capacity | 2 m³ |

| Dry Capacity | 3.000 lt |

| Compressed Concrete | 2.000 lt |

| Motor Power | 2 × 37 kW |

| Aggregate Bunker | |

| Aggregate Compartments | 4 pcs |

| Compartment Capacity | 15 m³ |

| Total Capacity | 60 m³ |

| Aggregate Weighing Conveyor and Mixer Feeding Conveyor | |

| Width | 1.000 mm |

| Length | ~15 m |

| Motor Power | 15 kW |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 1000 kg |

| Water Weighing Hopper | 500 kg |

| Additive Weighing Hopper | 50 kg |

| Cement Silo Equipment | |

| Cement Silo Capacity | 75–100 ton |

| Cement Silo Number | 1–4 pcs |

| Cement Screw Conveyor | Ø273 |

| Compressor | |

| Capacity | 700 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 4 kW |

| Optional | |

| Aggregate Loading System | |

| Aggregate Hopper Capacity | 7 m³ |

| Width | 800 mm |

| Length | ~17 m |

| Motor Power | 15 kW |

BM 100-S Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 100 m³/hour |

| Cycle Time | 50 mix/hour |

| Total Motor Power | 150–180 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Mixer Specifications | |

| Type | Twin Shaft |

| Mixer Capacity | 2 m³ |

| Dry Capacity | 3.000 lt |

| Compressed Concrete | 2.000 lt |

| MMotor Power | 2 × 37 kW |

| Aggregate Bunker | |

| Aggregate Compartments | 3–4 pcs |

| Compartment Capacity | 20–30 m³ |

| Total Capacity | 60–120 m³ |

| Aggregate Weighing Conveyor | |

| Width | 800 mm |

| Length | ~10 m |

| Motor Power | 11 kW |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 1.000 kg |

| Water Weighing Hopper | 500 kg |

| Additive Weighing Hopper | 50 kg |

| Mixer Feeding Conveyor | |

| Width | 1.000 mm |

| Length | ~15 m |

| Motor Power | 15 kW |

| Cement Silo Equipment | |

| Cement Silo Capacity | 75–100 ton |

| Cement Silo Number | 1–4 pcs |

| Cement Screw Conveyor | Ø273 |

| Compressor | |

| Capacity | 1.500 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 7,5 kW |

BM 120 Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 120 m³/hour |

| Cycle Time | 40 mix/hour |

| Total Motor Power | 200–220 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Mixer Specifications | |

| Type | Twin Shaft |

| Mixer Capacity | 3 m³ |

| Dry Capacity | 4.500 lt |

| Compressed Concrete | 3.000 lt |

| Motor Power | 2 × 55 kW |

| Aggregate Bunker | |

| Aggregate Compartments | 4 pcs |

| Compartment Capacity | 20 m³ |

| Total Capacity | 80 m³ |

| Aggregate Weighing Conveyor and Mixer Feeding Conveyor | |

| Width | 1.000 mm |

| Length | ~15 m |

| Motor Power | 15 kW |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 1.500 kg |

| Water Weighing Hopper | 800 kg |

| Additive Weighing Hopper | 50 kg |

| Cement Silo Equipment | |

| Cement Silo Capacity | 75–100 ton |

| Cement Silo Number | 2–4 pcs |

| Cement Screw Conveyor | Ø273 |

| Compressor | |

| Capacity | 700 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 4 kW |

| Optional | |

| Aggregate Loading System | |

| Aggregate Hopper Capacity | 7 m³ |

| Width | 800 mm |

| Length | ~17 m |

| Motor Power | 15 kW |

BM 120-S Mobile Concrete Batching Plants Technical Specifications

| Concrete Plant Capacity | |

|---|---|

| Compressed Concrete | 120 m³/hour |

| Cycle Time | 40 mix/hour |

| Total Motor Power | 200–220 kW |

| Voltage – Frequency | 380 V / 50 Hz |

| Mixer Specifications | |

| Type | Twin Shaft |

| Mixer Capacity | 3 m³ |

| Dry Capacity | 4.500 lt |

| Compressed Concrete | 3.000 lt |

| Motor Power | 2 × 55 kW |

| Aggregate Bunker | |

| Aggregate Compartments | 3 – 4 pcs |

| Compartment Capacity | 30 m³ |

| Total Capacity | 90–120 m³ |

| Aggregate Weighing Conveyor | |

| Width | 800 mm |

| Length | ~ 10 m |

| Motor Power | 11 kW |

| Weighers | |

| Aggregate Collecting Hopper | - |

| Cement Weighing Hopper | 1.500 kg |

| Water Weighing Hopper | 800 kg |

| Additive Weighing Hopper | 50 kg |

| Mixer Feeding Conveyor | |

| Width | 1.000 mm |

| Length | ~ 15 m |

| Motor Power | 15 kW |

| Cement Silo Equipment | |

| Cement Silo Capacity | 75–100 ton |

| Cement Silo Number | 2–4 pcs |

| Cement Screw Conveyor | Ø 273 |

| Compressor | |

| Capacity | 1.500 lt/dk |

| Working Pressure | 6–8 bar |

| Motor Power | 7.5 kW |