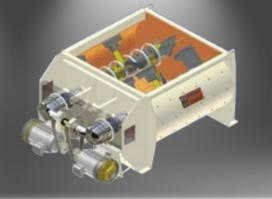

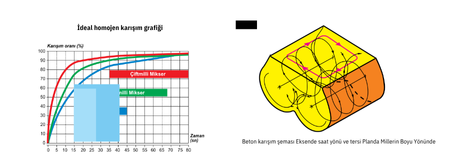

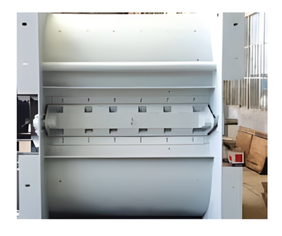

hanks to the angled design of the mixing paddles, the materials move both horizontally and vertically, creating a three-dimensional mixing motion that ensures maximum homogeneity in a short time.

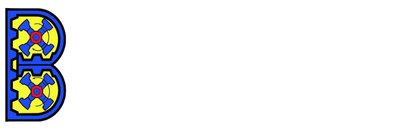

BTS Series Twin-Shaft Mixer Models

Bozdağ Engineering manufactures five different twin-shaft mixer models to meet various production capacity requirements:

| Model | Mixing Volume (Liters) | Compacted Concrete Capacity (Liters) | Application Area |

|---|---|---|---|

| BTS 3000-2000 | 3000 | 2000 | Medium-scale ready-mix concrete plants |

| BTS 4500-3000 | 4500 | 3000 | High-capacity concrete batching plants |

| BTS 6000-4000 | 6000 | 4000 | Large-scale infrastructure projects |

| BTS 6750-4500 | 6750 | 4500 | Precast and tunnel segment production |

| BTS 9000-6000 | 9000 | 6000 | Heavy-duty industrial concrete facilities |

All models are designed and manufactured with the same principles of high mixing quality, durability, and maintenance efficiency.