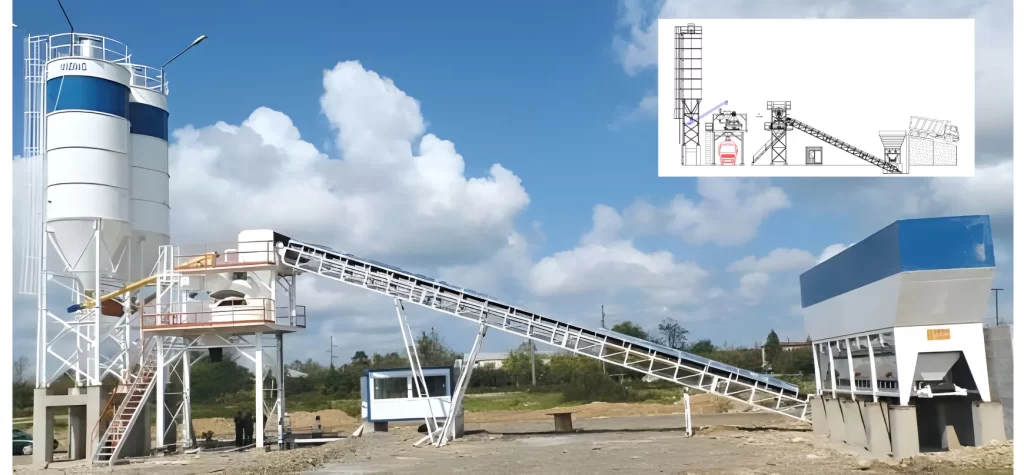

Stationary Concrete Batching Plants

Bozdağ Stationary Concrete Batching Plants stand out with their high performance, superior quality, and durability under all weather conditions — making them the preferred choice of professional construction companies. Designed for high-capacity and long-term projects such as dams, airports, high-speed rail lines, tunnels, and major infrastructure works, these plants deliver exceptional efficiency and reliability.

Bozdağ offers a wide range of models — BS 60, BS 100, BS 120, BS 160-180, BS 200, BS 204-D, BS 240, and BS 300 — to meet different production capacities and project requirements. Each model ensures maximum productivity, low maintenance costs, and long service life in ready-mix concrete production.

Engineering Excellence and Modular Design Advantage

Bozdağ stationary concrete plants feature a modular structure that allows for quick and easy installation. Thanks to their bolt-and-slide assembly system, installation can be completed within 5–6 days, even under challenging site conditions — without the need for welding. This flexibility also enables easy relocation between job sites when required.

All main components of the plants — excluding electric motors, gearboxes, and electronic parts — are manufactured in Bozdağ’s own facilities, ensuring high quality and tailor-made solutions for each project.

Efficiency-Oriented Layout and Project Planning

Bozdağ Engineering carefully plans the layout of each concrete batching plant based on site conditions and operational efficiency. By optimizing space usage, material flow, and energy consumption, operational costs are significantly reduced while maintaining maximum productivity.

Experience, Reliability, and Consistent Quality

With decades of engineering expertise, advanced manufacturing technology, and continuous R&D, Bozdağ Stationary Concrete Plants have become a trusted brand and industry leader. Each model is designed to deliver high performance, consistent quality, and long-term reliability.

Bozdağ Stationary Concrete Plants — from BS 60 to BS 300 — are the trusted production partners for professionals seeking dependable, high-capacity, and efficient concrete solutions.

BS 60 Stationary Concrete Batching Plant Technical Specifications

| Compressed Concrete | 60 m³/hour |

| Cycle Time | 60 mix/hour |

| Total Motor Power | 100–120 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Type | Planetary |

| Mixer Capacity | 1 m³ |

| Dry Capacity | 1.500 lt |

| Compressed Concrete | 1.000 lt |

| Motor Power | 45 kW |

| Compartments | 3–4 pcs |

| Compartment Capacity | 20–30 m³ |

| Total Capacity | 60–120 m³ |

| Width | 600–800 mm |

| Length | 8–30 m |

| Motor Power | 7,5–11 kW |

| Aggregate Collecting Hopper | 2.500 kg |

| Cement Weighing Hopper | 800 kg |

| Water Weighing Hopper | 500 kg |

| Additive Weighing Hopper | 50 kg |

| Width | 800 mm |

| Length | ~24 m |

| Motor Power | 16–18,5 kW |

| Silo Capacity | 50–75–100 ton |

| Number of Silos | 1–4 pcs |

| Cement Screw Conveyor | Φ219 |

| Capacity | 1.200 lt/min |

| Working Pressure | 6 bar |

| Motor Power | 5,5 kW |

BS 100 Stationary Concrete Batching Plant Technical Specifications

| Compressed Concrete | 100 m³/hour |

| Cycle Time | 60 mix/hour |

| Total Motor Power | 160–210 kW |

| Voltage - Frequency | 380V / 50 Hz |

| Type | Twin Shaft |

| Mixer Capacity | 2 m³ |

| Dry Capacity | 3.000 lt |

| Compressed Concrete | 2.000 lt |

| Motor Power | 2 × 37 kW |

| Compartments | 3–6 pcs |

| Compartment Capacity | 30–50 m³ |

| Total Capacity | 90–250 m³ |

| Width | 800 mm |

| Length | ~25 m – 30 m |

| Motor Power | 2×5,5 kW |

| Aggregate Collecting Hopper | 6.000 kg |

| Cement Weighing Hopper | 1.000 kg |

| Water Weighing Hopper | 800 kg |

| Additive Weighing Hopper | 50 kg |

| Width | 1.000 mm |

| Length | ~30 m |

| Motor Power | 30 kW |

| Cement Silo Capacity | 75–100 ton |

| Number of Silos | 1–4 pcs |

| Cement Screw Conveyor | Φ273 |

| Capacity | 1.000 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 7,5 kW |

BS 120 Stationary Concrete Batching Plant Technical Specifications

| Compressed Concrete | 120 m³/hour |

| Cycle Time | 40 mix/hour |

| Total Motor Power | 200–220 kW |

| Voltage – Frequency | 380 V / 50 Hz |

| Type | Twin Shaft |

| Mixer Capacity | 3 m³ |

| Dry Capacity | 4.500 lt |

| Compressed Concrete | 3.000 lt |

| Motor Power | 2 × 55 kW |

| Compartments | 4–6 pcs |

| Compartment Capacity | 30–50 m³ |

| Total Capacity | 120–300 m³ |

| Width | 800 mm |

| Length | ~25 m – 30 m |

| Motor Power | 2 × 7,5 – 11 kW |

| Aggregate Collecting Hopper | 7.000 kg |

| Cement Weighing Hopper | 1.000 kg |

| Water Weighing Hopper | 800 kg |

| Additive Weighing Hopper | 50 kg |

| Width | 1.000 mm |

| Length | ~30 m |

| Motor Power | 30 kW |

| Cement Silo Capacity | 75–100 ton |

| Number of Silos | 1–4 pcs |

| Cement Screw Conveyor | Φ273 |

| Capacity | 1.200 lt/dk |

| Working Pressure | 6–8 bar |

| Motor Power | 7,5 kW |

BS 160-180 Stationary Concrete Batching Plant Technical Specifications

| Compressed Concrete | 160 m³/hour |

| Cycle Time | 40 mix/hour |

| Total Motor Power | 240–260 kW |

| Voltage – Frequency | 380V / 50 Hz |

| Type | Twin Shaft |

| Mixer Capacity | 4 m³ |

| Dry Capacity | 6.000 lt |

| Compressed Concrete | 4.000 lt |

| Motor Power | 2 × 75 kW – 2 × 90 kW |

| Compartments | 4–6 pcs |

| Compartment Capacity | 30–50 m³ |

| Total Capacity | 120–300 m³ |

| Width | 800 mm – 1.000 mm |

| Length | ~25 m – 30 m |

| Motor Power | 2 × 7,5 kW – 11 kW |

| Aggregate Collecting Hopper | 9.600 kg |

| Cement Weighing Hopper | 1.000 kg |

| Water Weighing Hopper | 800 kg |

| Additive Weighing Hopper | 50 kg |

| Width | 1.200 mm |

| Length | ~30 m – 36 m |

| Motor Power | 37–45 kW |

| Cement Silo Capacity | 100–200 ton |

| Number of Silos | 2–4 pcs |

| Cement Screw Conveyor | Φ323 |

| Capacity | 1.600 lt/min |

| Working Pressure | 6–8 bar |

| Motor Power | 7,5 kW |

BS 240 Stationary Concrete Batching Plant Technical Specifications

| Compressed Concrete | 240 m³ / hour |

| Cycle Time | 40 mix / hour |

| Total Motor Power | 330–360 kW |

| Voltage – Frequency | 380 V / 50 Hz |

| Type | Twin Shaft |

| Mixer Capacity | 6 m³ |

| Dry Capacity | 9 000 lt |

| Compressed Concrete | 6 000 lt |

| Motor Power | 2 × 55 kW |

| Compartments | 4 – 8 pcs |

| Compartment Capacity | 30 – 50 m³ |

| Total Capacity | 120 – 400 m³ |

| Width | 800 mm – 1 000 mm |

| Length | ≈ 25 m – ≈ 40 m |

| Motor Power | 2 × 7.5 kW – 11 kW |

| Aggregate Collecting Hopper | 14 000 kg |

| Cement Weighing Hopper | 3 000 kg |

| Water Weighing Hopper | 1 600 kg |

| Additive Weighing Hopper | 100 kg |

| Width | 1 200 mm |

| Length | ≈ 30 – 36 m |

| Motor Power | 2 × 30 – 45 kW |

| Cement Silo Capacity | 100 – 200 ton |

| Number of Silos | 2 – 4 pcs |

| Cement Screw Conveyor | Φ 325 |

| Capacity | 2 400 lt/min |

| Working Pressure | 6 – 8 bar |

| Motor Power | 18.5 kW |

BS 200/BS 240-D/BS 300 Stationary Concrete Batching Plant Technical Specifications

| Concrete Plant Capacity | BS 200 | BS 240-D | BS 300 |

|---|---|---|---|

| Compressed Concrete | 200 m³/hour | 240 m³/hour | 300 m³/hour |

| Cycle Time | 2×50 mix/hour | 2×55 mix/hour | 2×75 mix/hour |

| Total Motor Power | 350-380 kW | 350-380 kW | 350-380 kW |

| Voltage - Frequency | 380V / 50 Hz | 380V / 50 Hz | 380V / 50 Hz |

| Mixer Specifications | |||

| Type | Twin Shaft | ||

| Mixer Capacity | 2×3 m³ | 2×4 m³ | 2×4.5 m³ |

| Dry Capacity | 9.000 lt | 9.000 lt | 9.000 lt |

| Compressed Concrete | 6.000 lt | 6.000 lt | 6.000 lt |

| Motor Power | 2×45 kW | 2×55 kW | 2×75 kW |

| Aggregate Bunker | |||

| Aggregate Compartments | 4–8 pcs | 4–8 pcs | 4–8 pcs |

| Compartment Capacity | 30–50 m³ | 30–50 m³ | 30–50 m³ |

| Total Capacity | 120–400 m³ | 120–400 m³ | 120–400 m³ |

| Aggregate Weighing Conveyor | |||

| Width | 800 mm | 800 mm | 1000 mm |

| Length | 2×5 m | 2×5 m | 2×10 m |

| Motor Power | 2×5.5 kW | 2×7.5 kW | 11–15 kW |

| Weighers | |||

| Aggregate Collecting Hopper | 14.000 kg | 14.000 kg | 14.000 kg |

| Cement Weighing Hopper | 3.000 kg | 3.000 kg | 3.000 kg |

| Water Weighing Hopper | 1.600 kg | 1.600 kg | 1.600 kg |

| Additive Weighing Hopper | 100 kg | 100 kg | 100 kg |

| Mixer Feeding Conveyor | |||

| Width | 1.200 mm | 1.200 mm | 1.200 mm |

| Length | ~30–36 m | ~30–36 m | ~30–36 m |

| Motor Power | 2×30–37 kW | 2×30–37 kW | 2×30–45 kW |

| Cement Silo & Equipments | |||

| Cement Silo Capacity | 100–200 ton | 100–200 ton | 100–200 ton |

| Cement Silo Number | 2–4 adet | 2–4 adet | 2–4 adet |

| Cement Screw Conveyor | ø273 | ø273 | ø323 |

| Compressor | |||

| Capacity | 1.400 lt/dk | 1.400 lt/min | 1.400 lt/min – 2.400 lt/min |

| Working Pressure | 6–8 bar | 6–8 bar | 6–8 bar |

| Motor Power | 7,5 kW | 7,5 kW | 18,5 kW |